Archive for March, 2017

Reflow Soldering Still Doesn’t #*&@ Work

After four semi-failed attempts, I am not destined for success with reflow soldering using an electric hotplate. At least not with chips having a 0.5 mm pin spacing. At this point I’m only motivated to continue on by pure stubbornness, as any hope that this would “save me time” is long gone.

Building on the results of my most recent previous attempt, I tried again with a new aluminum plate and new solder paste. I was pinning my hopes on the new solder paste, after having discovered that my original solder paste syringe had already expired by the time I bought it. I suspected that the poor wetting behavior and large number of solder bridges were due to spoiled paste. Judging by its date code, the new solder paste was only five months old, and before purchase it was stored refrigerated by DigiKey to prevent spoilage. They shipped it in a cold pack, at least, so I assume it was refrigerated before that.

The results were sadly the same as my prior attempts: poor wetting and tons of solder bridges. Apparently it wasn’t my solder paste’s fault, but my technique. The video shows the story in all its gory detail.

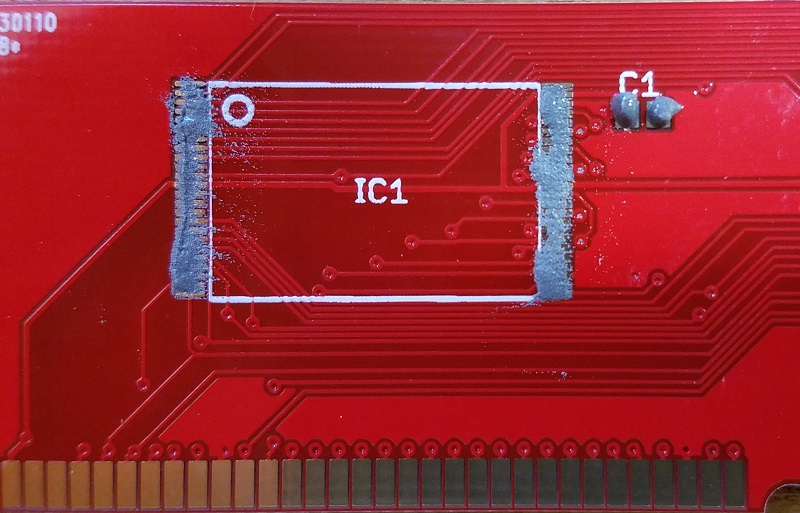

After having more-or-less exhausted the other possibilities, I’ve come to the conclusion that using a stencil must be essential for success. Maybe no-stencil application of solder paste direct from the syringe can work for components with nice big pads, but not for chips with 0.5 mm pin spacing, unless you want to spend time afterwards manually fixing solder bridges with an iron. Lacking a stencil, I prepared a second PCB by carefully smoothing out the solder paste with a cotton swab, trying to approximate the result of a stencil. I couldn’t avoid getting solder paste between the pads, of course, but I tried to get a thin and even coating over the entire pad area. Here’s what this second attempt looked like, prior to placing the components:

Looking at this photo now, the solder paste coating is kind of terrible, but at the time it seemed good. It’s hard to appreciate just how small those pads are, and it’s very difficult to spread the solder paste around evenly with a cotton swab.

After reflow, this second board turned out better than the first. There were fewer solder bridges, and the overall distribution of solder was more uniform. It was still far from acceptable, though.

Now it’s time for a decision. Do I order a stencil, and try again? Out of pure stubbornness and a desire to see this finally work, I want to say yes. But the practical part of my brain says no, I’ve already proven that it’s faster to assemble these boards with my current technique of drag-soldering. That makes success or failure with reflow and a stencil irrelevant. Maybe I’ll try it anyway for “educational purposes” – a sure way to justify any questionable idea.

Read 16 comments and join the conversationBMOW on https

The entire Big Mess o’ Wires site should now be usable via the encrypted https protocol. I had some trouble with this a year ago, when I unintentionally enabled https for the blog and discovered that lots of things broke. At the time, I wasn’t ready to make the effort to fix it all, so I implemented a security-unfriendly solution of redirecting all https requests to plain unencrypted http instead. As of today that’s no longer necessary, which is good news.

The BMOW store has always been https-only, but I never thought the blog section needed https. After all, there are no passwords or financial data or other secrets to protect here. The trouble with enabling https for the blog is the zillions of hard-coded references to http://www.bigmessowires.com in the text of old posts, image URLs, forms, and elsewhere. Http elements in an https page cause the browser to give security warnings, and some features like forms just plain don’t work. Fixing this was much less trouble than I’d feared – it only took one careful search-and-replace operation on the database to fix most of them. Yes I have backups, but I still quadruple-checked my search parameters before bulk-modifying 10+ years of posts.

Why is encrypted https useful for browsing public information, like the contents of the BMOW blog? Depending on your level of paranoia, it’s not. However, if you’re especially concerned about privacy, browsing the blog using https instead of http will provide some extra protection. It will prevent snoopers from seeing exactly what content you’re viewing on the BMOW site, or what you posted in the content forms. They’ll still be able to see that you interacted with bigmessowires.com, but no details about what you did there.

Https also provides more confidence that the content you’re viewing is the same content that the server sent you. With an unencrypted connection, a man-in-the-middle (your ISP, for example) could modify the pages you’re viewing on the fly, inserting extra advertisements or tracking elements or malware. I’m not certain this protection is completely guaranteed, however. While I’m no expert, I’ve read about SSL interception proxies that sit in the middle of an https connection, while making both ends think they’re communicating directly with the other end. Nevertheless, using https for all your web browsing should greatly reduce the risk of this type of tampering.

Read 2 comments and join the conversationHot Plate + Aluminum Pie Pan = No Joy

I’m back with another episode of my DIY reflow soldering adventures! The first attempt using hot air didn’t go well, and the second attempt with a hot plate and half-inch thick aluminum block wasn’t great either. This time I used a lightweight disposable aluminum pie plate instead of the half-inch aluminum block. The idea was to reduce the thermal lag observed with the thicker block, and make it easier to remove the PCB from the hot plate after reflow was complete.

The lightweight pie plate proved to be a bad idea. Its bottom was embossed with small ridges, and was slightly warped and dented. The pie plate wouldn’t sit flat on the burner, and the PCB wouldn’t sit flat on the pie plate. To make matters worse, the pie plate also deformed as it heated. With such poor thermal contact between the burner, pie plate, and PCB, the PCB heated very slowly and unevenly. It did eventually reflow successfully after 10 minutes of heating, but I had to push down one side of the PCB with tweezers to improve the thermal contact.

The results of reflowing looked similar to my first reflow attempt using hot air: not good. There were solder bridges everywhere, but also clear evidence that many pads were dry, with only a portion of the pad area covered in solder. The photo above shows an example. The bare pads are ENIG plated and have a gold color. After reflow is finished it’s easy to see the areas that are still gold-colored, where solder never flowed. Ideally there should be no such areas.

Such poor flowing of solder makes me think the flux in my solder paste has gone bad. A few days ago I discovered that my newly-purchased paste was already beyond its shelf life, so I’ve got more solder paste on order. Hopefully that will result in better solder flow, with pads that are completely covered in solder, and few or no solder bridges.

It’s All About Time

My main goal with this whole reflow adventure is speed. I hope to assemble batches of a few dozen ROM-inator II PCBs faster than I can by drag-soldering with a standard iron. I can finish one PCB every 10 minutes with drag-soldering, and at least half of that time is consumed by fixing solder bridges. If I have to spend a similar amount of time fixing solder bridges on the reflowed PCBs as on the drag-soldered ones, then it’s unlikely reflow will provide the speed-up I’m looking for.

Even if new solder paste resolves my solder bridge problems, I’m also concerned by the setup time required to dispense the solder paste and position the chips. I timed these steps, and they took 6 minutes, all before the reflow process even started. With practice I could probably speed that up by a minute or two, but that still puts the total time including reflow close to 10 minutes, even assuming everything goes perfectly with no solder bridges. Only by reflowing multiple PCBs at once could I hope to save any appreciable time vs drag-soldering.

The video shows the entire process end to end, including dispensing the solder paste, placing the chips, reflow heating, and saying “woah” and “oh my gosh” about 20 times. I apologize for the poor quality of the video. My hand often blocks the view, and the camera isn’t positioned well to show the solder reflow in detail. Maybe you’ll find the “authentic amateur” style amusing!

Read 8 comments and join the conversationHot Plate Reflow Soldering: Round 1

Last week’s attempt at reflow soldering with hot air didn’t go very well. Today I gave it another try with an electric hot plate, and it still didn’t go well, but maybe I learned something in the process. Will the third attempt bring success?

My goal this time wasn’t really to solder anything important, but simply to test how quickly the hot plate heats up, and where on the control dial’s warm-low-medium-high scale will produce the necessary temperatures. I used an infrared thermometer to measure the surface temperature of the burner.

Part 1 – Naked Hot Plate

With nothing on it, and the dial set to “medium”, the hot plate temperature increased by about 100 degrees Celsius per minute, reaching the 183 C melting point of solder after roughly 90 seconds. From there it kept on going to 300+ C before I aborted the test, so “medium” was clearly too hot. I later found a setting just above “warm” that produced a steady temperature about 150 C, which is about right for pre-soak. Unfortunately there was a large amount of temperature variation between different areas of the burner – about 45 deg C. This could cause problems form uneven heating if a PCB were placed directly on the burner.

Part 2 – With Aluminum Heat Spreader

For my second test, I placed a 6 x 6 x 0.5 inch aluminum block on top of the burner, to use as a heat spreader. I put an old PCB on the aluminum block, with solder paste and a few small capacitors. It was quickly obvious that the aluminum block was far too thick for this purpose, with much too high a thermal inertia (what’s the right term for this?). Its temperature barely rose at all initially, but then it continued to climb for several minutes even after the hot plate was turned off, as heat was absorbed from the still-warm hot plate.

When the aluminum and PCB reached about 100 C, I decided to turn the hot plate back on to “medium” and just let it rip. The temperature rose by about 15 deg/minute, which is pretty slow. Once it reached roughly 210 C and the solder paste was nice and melted, I turned off the hot plate, but the temperature kept going up! The hot plate burner was probably still at 300+ C, and the aluminum was still slowly absorbing heat. I had to slide the PCB off the aluminum while the solder was still molten in order to allow it to cool. Not good.

The temperature variation between different areas of the aluminum was only about 5 deg C. But the temperature variation between different areas of the PCB sitting on the aluminum was as much as 90 deg C – yikes! The test PCB was very slightly bowed, resulting in some areas not actually touching the aluminum, making them much colder than other areas just an inch away. I’m not sure how to fix that. Maybe I could press down on the PCB with a non-conductive tool while it’s cooking, but that would make it difficult to use the thermometer or adjust the control dial, and would make it almost impossible to reflow more than one board at a time.

I was surprised to see how long it took the hot plate to cool off after use. More than an hour after finishing these tests, the aluminum block was still at 55 C. That could be a problem if I need to run several batches of PCBs through hot plate reflow. Will I need to wait 10, 20, 30+ minutes between batches, to allow the hot plate to cool?

What Next?

Maybe a reflow toaster would be easier than a reflow hot plate, but most of the advice I’ve heard says the opposite. I’m also very reluctant to use a toaster, since even a small toaster would be hard to fit in my work area, and it’s tough to see inside a toaster to observe what’s happening during reflow. I really like the open loop simplicity of the hot plate method, and would prefer not to mess around with toasters and thermocouples and temperature controllers unless there’s no alternative. If it comes to that, I might just give up on reflow and stick with hand soldering.

For the next test, I’ll use a much thinner aluminum plate, or maybe just a couple of sheets of aluminum foil. I think the 100 deg/minute warming I observed without the aluminum block is actually about the right rate for reaching the pre-soak temperature, if I can find the necessary control setting to pause it there for a minute afterwards. But I probably still need something to help even out the hot spots on the hot plate burner, to ensure the PCB is warmed evenly.

Read 6 comments and join the conversationCase Packing Time Lapse Video

Frosted Ice cases for Floppy Emu are back in stock at the BMOW store, and I took the opportunity to make a time lapse video of the case packing process. Where does all the time go? Last week’s video featured the behind-the-scenes order fulfillment process, in which pre-bagged case kits were already prepared. Today’s video shows where those came from.

The plastic case parts come pre-made on large laser-cut sheets from a third party, with enough parts for seven cases per sheet. The parts must be pulled out, sorted, and placed into individual bags. Fastener hardware is added to each bag, before it’s sealed and ready for sale. Extra light pipes from clear sheets are saved to be reused with opaque sheets for Snow White cases. It’s one more unglamorous task that consumes surprising amounts of time.

Things to find in the video: Macintosh Family Hardware Reference guide, Imagewriter II printer.

Read 2 comments and join the conversationReflow Soldering Fail

I’ve long wanted to try reflow soldering of surface mount components, using solder paste and hot air or a hot skillet, and I recently had an opportunity to try. Unfortunately the results were very poor, and I was left wondering what I did wrong. Compared to my normal method of drag-soldering surface mount chips with a standard iron and liberal amounts of flux, the reflow method with solder paste took more than twice as long and led to worse results overall.

My test case was the ROM-inator II SIMM, which has a couple of chips with a 0.5 mm pin spacing. With my normal soldering iron, I can tack down a few corner pins, drag solder the rest of the pins, and then use desoldering braid to clean up the inevitable solder bridges that sometimes occur between adjacent pins. It’s something of a slow and tedious method, but it works.

For this reflow experiment, I used a syringe of MG Chemicals Leaded Solder Paste. The needle on the MG syringe is quite large, and the bead of solder paste it dispenses is far too wide for detailed surface mount work. I dispensed about 0.1 mL of the solder paste into a second 1 mL syringe with a 22 gauge needle, which allowed me to create a nice narrow line of paste with very little finger pressure on the syringe’s plunger.

Solder paste has a limited shelf life, and you’re supposed to keep it refrigerated to help preserve it. I believe the flux in the solder paste evaporates more slowly at low temperatures. I made a conscious choice not to refrigerate, accepting that the paste would spoil faster than normal, because I wasn’t excited about keeping leaded solder where I keep my food. For this test, the solder paste was just one week old, and should still have been quite fresh.

I didn’t use a PCB stencil, because I didn’t have one, and because I was skeptical I could hand-position a stencil to sub-millimeter accuracy anyway. I also wasn’t excited about the mess created by squeegeeing solder paste across a stencil. Instead, following some advice from a tutorial, I used the syringe to dispense a very narrow bead of solder paste straight down the line of pads on the PCB. While it might seem that this would cause all the pins to be soldered to their neighbors instead of to the pads, the magic of flux and solder surface tension should have made it work OK.

Using tweezers, I positioned the chips on the pads, aligning them as accurately as I could. The MG solder paste had a nice amount of stickiness to it, holding each chip steadily in place after I’d positioned it. That magic surface tension of solder should have helped here too, causing the chip to “snap” into perfect alignment with the pads once the solder began to melt.

I used a hot air rework station to heat the pads, and before long the solder paste melted into a silvery and shiny color. I let it go for a few more seconds to ensure everything was fully melted, then removed the hot air and let the board cool.

Results

Despite having put down a very narrow bead of paste, many of the pins were bridged together. In this respect it was as bad or worse than my hand-soldering efforts, which was disappointing. But while some pins became bridged to their neighbors, other pins had too little solder, or looked completely dry. Overall I’d say the row of pins looked like it had too little solder rather than too much, so I don’t think the bridged pins were due to applying too large a bead of solder paste.

A second and more serious problem was the positioning of the chip. When hand soldering with an iron I can usually align those 0.5 mm pins with their pads fairly accurately, but the gray solder paste made the task more difficult this time. After dispensing the solder paste and placing the chip, but before melting the solder, the row of pins looked like a silver and gray blur. It was very tough to see if it was positioned accurately. The result was that two of my chips were positioned with the pins misaligned far enough from the pads to create a mess I was never able to fix. It only takes about 0.2 mm of misalignment to create a major problem with pins this closely spaced.

Even when the chips were aligned properly, I still had to go back and forth over each row of pins with the iron and flux, to fix the solder bridges and flow more solder onto pads that had too little. In effect, I had to drag solder the chip after having already reflow soldered it. Definitely not an improvement over the old method.

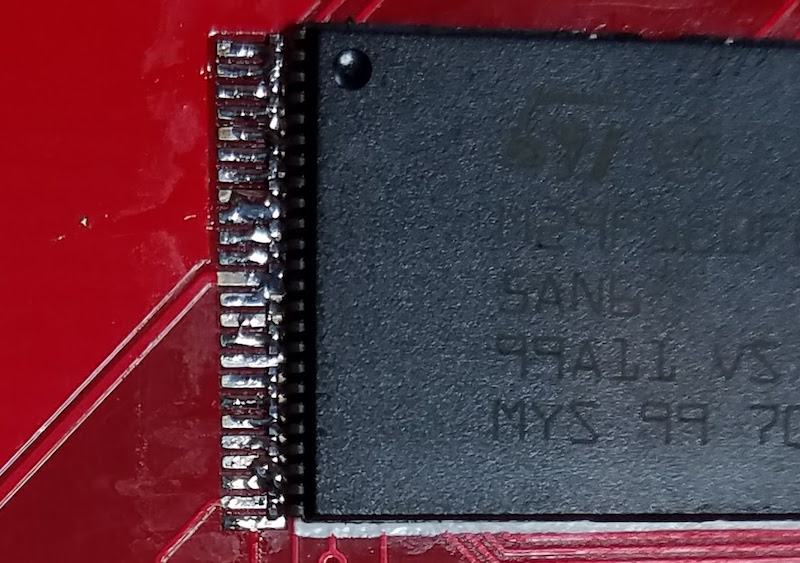

I built four ROM-inator II SIMMS this way, refining my technique each time in the hopes that the results would improve, but they never really did. Two of the four SIMMs couldn’t be salvaged, and had to be scrapped.

The title photo above shows one of those reject SIMMs, with a poorly aligned chip, after I’d made about 50 passes with an iron, flux, and desoldering braid trying to clean it up. It’s a mess, which is why I like the photo, but don’t take the photo as being a literal example of the results immediately after reflowing. I should have thought to take some photos after the reflow process, but before I’d touched any pins with an iron. It looked much cleaner and nicer then, but was misaligned and had many solder bridges and many pads with low or no visible solder.

Explanation

Why did this work so poorly? I don’t think it was the absence of a stencil. Attempting to position the chip smeared the solder paste around, so even if I’d had a stencil and used it perfectly, I still would have had smeared paste between the pads anyway.

I also don’t think my hand-dispensed solder paste bead was the problem. Using the 1 mL syringe, I was able to dispense a nice and even bead that was about as wide as a single pad, roughly 0.3 mm or so. Given the occasional low- and no-solder pads I observed, I probably had too little solder if anything, not too much.

Maybe 0.5 mm spaced pins are simply too small and close to be reflow soldered using this method? For comparison, I used the same reflow method to solder some 0805 sized SMD capacitors on this PCB, and it worked perfectly every time. No doubt larger sized components are easier to solder correctly, but I’m dubious that 0.5 mm pin spacing is beyond some threshold that can’t be reflow soldered using this method.

Maybe the temperature profile during reflow was far enough off to cause major problems? A real reflow process in a commercial oven would have a preheat phase about 4 minutes long, then an actual reflow time (above the solder’s melting point) of 60-90 seconds. My hot air method was much faster than that: point the hot air tool at the pads, wait maybe ~30 seconds for the solder paste to melt, wait another ~10 seconds to make sure it’s completely melted and reflowed everywhere, then remove the hot air.

Maybe the solder paste had already gone bad after a week at room temperature. That seems hard to believe, but it would explain the apparently poor wetting that I observed, with frequent solder bridges at the same time as other pins were dry, and the failure of the chip to snap into the proper alignment when the solder melted. The MG Chemicals syringe doesn’t have a date on it, but it’s marked with lot code 15-349 and was purchased new last week. If 15-349 means it was made in 2015 (on the 349th day perhaps), and the syringe has been stored at room temperature in an Amazon warehouse since then, that would certainly be a problem.

Maybe the way I heated the pads with the hot air gun caused a problem? This seems plausible. The heat was localized to a small area, so I would reflow the pins on one side of the chip, then reflow the other side 20 seconds later. Perhaps if the entire PCB had reached reflow temperature at the same time, using an oven or skillet, I might have had better results.

Any other good theories?

Read 12 comments and join the conversation